Things You Should Know about 3D Scanning

With 3D printing technology, it is possible

to print just not physical objects, but even human organs. Whether you need a

piece of souvenir, or want to present a personalized gift, getting it 3D

printed is a probable. And 3D scanners have heightened this probability

tremendously. In fact, 3D scanners have added creativity, convenience, speed, accuracy,

and flexibility in the printing process owing to their ability to capture

measurements of any object and transform into three-dimensional digital models.

No wonder services of 3D scanning Melbourne are opted by engineers,

architectures, designers, jewelers, and manufacturing units from different

fields. Know these five things about 3D scanning.

3D scanning has helped overcome 3D

printing limitations

Though user-friendly software were used for

3D printing, it wasn't that efficient to transform objects into 3D modules.

Neither had it offered total control to tweak and make changes as required.

Simply speaking, manipulation, and tailoring the scanned object before printing

was impossible. As 3D scanner technology came into scene, capturing measurements

of any physical objects with and without any contact with the subject object

and transforming into digital form has become possible.

3D scanning has revolutionized teaching

No doubt, learning math, history,

geography, and engineering subjects has become easy with 3D printing. But

credit goes to 3D scanners as well. With the help of scanning, educational

institutions are able to scan any ancient objects, manuscript, etc. for

creating digital records and documents. Students can also download those prints

and use it for learning. Further, with 3D scanning, schools and universities

can literally print mathematical formulas for teaching and making students

understand better.

3D scanning has bridged the gap between

physical and digital worlds

Capturing complete features of objects

relative to their shape, size, colour, and dimensions is possible with 3D

scanning. Moreover, the captured data can be also be manipulated and customized

according to needs. Whether one needs partial or complete physical data of an

object, 3D scanners can do that job with ease. There is also no need to touch

the physical object for scanning by using the latest generation 3D scanners.

Where 3D scanning is used?

3D scanning is used to obtain high-density

physical data of engineering, architecture, and any other types of physical

objects you need to 3D print. It is best used for reverse engineering where

engineers can see, test, and improve their design with prototypes. It is used

for measuring, archiving, accurate recording, and repair of the object scanned

digitally. The best use of 3D scanning above all is, to duplicate existing

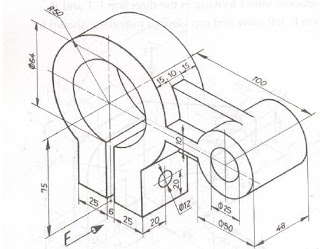

models accurately and modify them. For mechanical engineering projects where

drafting and drawings are the vital, use 3D CAD modeling as well.

How 3D scanners work

Depending on what type of 3D scanner being

in use, you can measure a physical object in three-dimensional by contacting it

with the surface of the object or without any contact. The former type of

scanner falls in “contact scanners” whereas the latter in non-contact scanners.

The non-contact scanners use laser light for collecting information of an

object. However, the only limitation of both scanners is, they can capture data

of only those parts where they are in contact and where the laser light has

fallen. Therefore, positioning of 3D scanners is important for complete 3D

rendering. This means, you have to perform scanning for more than once.

However, scanning any number of times is faster due to improvement in 3D

scanning technology. Also know that only the best 3D scanning serviceprovider in Melbourne will help such scanner.

3D scanning is fast and accurate is and a

revolutionary technology that is taking engineering, manufacturing, archiving,

and inspecting to the next level. For comprehensive 3D scanning service,

contact Zeal CAD Services, Melbourne, Australia. Outsource your 3D

CAD drawing projects to this reputed service-provider and save your time

and cost.

Comments

Post a Comment